新聞與活動

The advantages of AC-DC Brick Power Solution

02

Dec

Dec 2, 2022

Premises:

While we look at AC/DC power supplies on the market, the most commonly seen forms are open-frame, case enclosure (with fan), adapter types etc. Nowadays, due to the trend of chasing the higher power density and the smaller size for power solutions, brick power supplies have been introduced to the AC/DC category with some advantages. In this article, we will talk about the concept of AC/DC brick type power supply and the advantages while compared to traditional power supplies.

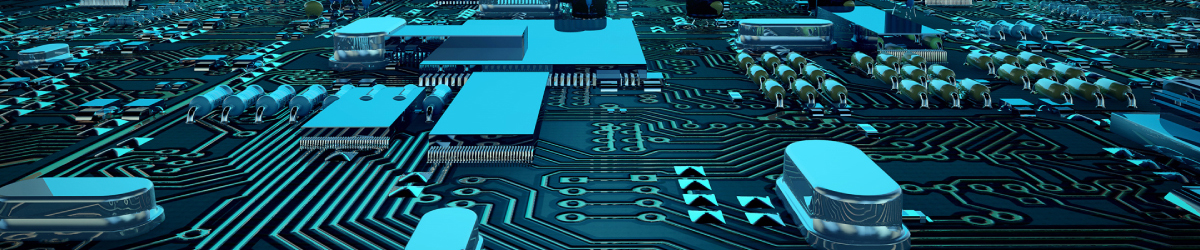

Brick power - Origin and size definition

The standard size of brick type power was announced by Distributed-Power Open Standard Alliance (DOSA) around year of 2010. The purpose was to standardize the footprint and make it easier for design engineers to source on the market. The size could be from Full-Brick to 1/32 size as follows:

Fig.1 Brick Power Size standard (By DOSA)

Brick power design - from DC/DC to AC/DC

Most of the early brick power supplies began with DC/DC converters between 50 to 100 watts. They were utilized in Distributed Power Architecture (DPA) from 48V to 12V and 12V to lower voltage (e.g. 5V or 3.3V). As the new technologies of components and advanced planar transformers developed, the higher wattage could be squeezed into a smaller package and increase the power density. In the early days, most power boards were designed with the bridge filter or power factor correction (PFC) discrete circuitry at the front end and then connected with DC/DC converter for needed voltage output.

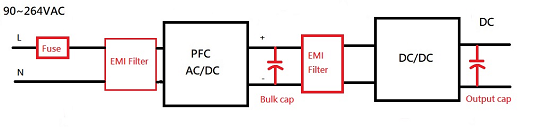

When the AC/DC brick type power came out, it reduced the design complexity by reducing the component on the power board. The system engineers only need to add the key components such as fuse, EMI filter, electrolytic capacitors etc. on the system board for the AC/DC brick power as the total power solution by following the technical guideline. It is simpler and saves more time when compared to building the entire front-end circuitry on the power board. See the Fig. 2 which is the AC/DC block diagram.

Fig.2 AC/DC power block diagram

Advantages of AC/DC brick power - compact size, lower profile & heat dissipation

When compared to other types of AC/DC power supply, the brick power has the advantages of compact size and lower profile. In addition, the encapsulated package provides the protection for internal electronic components from outer dust or humidity. The glue inside the brick power helps the brick power dissipate heat evenly from the module and prevents heat gathering on certain points.

The AC/DC brick type power could be mounted on the PCB board and pass-through wave soldering with other SMT components together, which saves time for installation.

Moreover, an AC/DC brick power equips an aluminum baseplate on the top for cooling purposes. Fanless solution is possible if attached on an additional system cooling plate. With the help of baseplate cooling solution, the operation temperature could be up to 100 ℃ if it is able to maintain case temperature under 85 ℃. This feature greatly fits in the application that the system case (or heatsink) directly contacts with outer environment and then directs the heat out of the power module easily. For those typical types of AC/DC power supply, their upper limit of the operating temperature would be only around 60℃~70℃ and they also require airflow for cooling purpose.

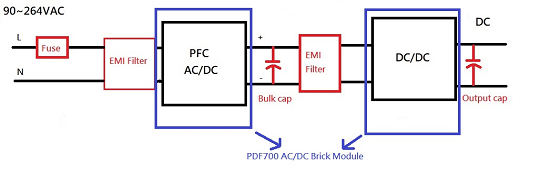

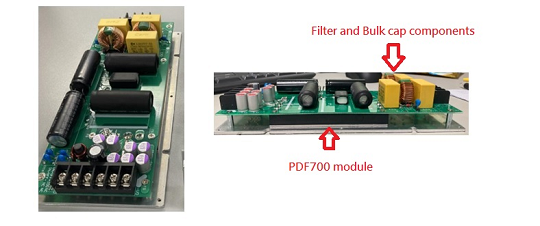

The better reliability is also another advantage of AC/DC brick power. Generally, an AC/DC brick power usually does not include electrolytic capacitors internally which extends its lifetime. Cincon PDF700S series could be the great example. The Fig. 3 and Fig. 4 show the diagram and the PDF700S-CMFC which is the solution with the needed external components.

Fig. 3 PDF700 AC/DC Brick module in block diagram

Fig. 4 PDF700-CMFC (The built-in external component set)

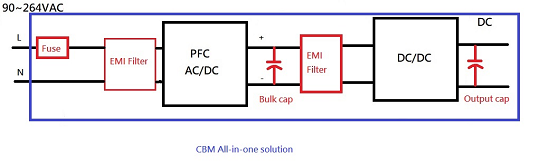

The new generation of AC/DC brick power with all-in-one solution - CBM series

As the global supply chain crisis of material shortage continued, souring the materials for PCBA became a big headache. Many customers were looking for turn-key solutions instead of building their power boards by souring all other filtering components. To overcome the problem, Cincon provides CBM series which is the AC/DC brick all-in-one solution. All the filtering components (e.g. inductor and capacitors) and the bulk cap are included inside the brick module. It could be directly used without additional filters and pass EN55032 Class B standard. Fig. 5 is the block for your reference.

Fig. 5 CBM concept in block diagram

PFC circuitry in half- brick module

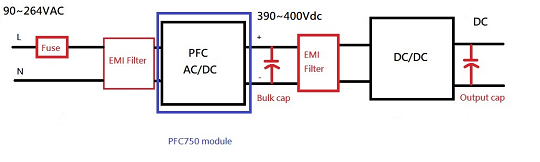

Besides, Cincon also provides the 750W PFC module solution. It is suitable to be placed at the AC/DC front-end and provides the power system with high power factor (PF) value to pass energy standard requirements. With the higher PF, the system could reduce input current for lower transmission lost. Also, with the output voltage around 390 to 400Vdc, the system hold-up time could be longer than that of the system with simple bridge rectifier front end (between 160 to 330Vdc output).

Fig. 6 PFC750 module in block diagram

Cincon is your brick power solution specialist

Cincon has sophisticated experiences in power supply design for more than 30 years. We have helped numerous system engineers develop their product power systems. We offer various kinds of AC/DC brick power solutions:

| Model | Type | Wattage | Input Voltage | Output Voltage |

| PDF700S | Full-brick AC/DC module |

700W | 90~264Vac | 12V, 24V, 28V, 48V, 56V |

| PFC750 | Half-Brick PFC module |

750W | 90~264Vac | 390V |

| CBM70S | Half-brick AC/DC power supply |

70W | 90~264Vac | 12V, 24V, 36V, 48V |

| CBM101S | Full-brick AC/DC power supply |

100W | 90~264Vac | 12V, 24V, 28V, 36V, 48V |

Contact sales@cincon.com.tw for support.